第1页 / 共7页

试读已结束,还剩6页,您可下载完整版后进行离线阅读

THE END

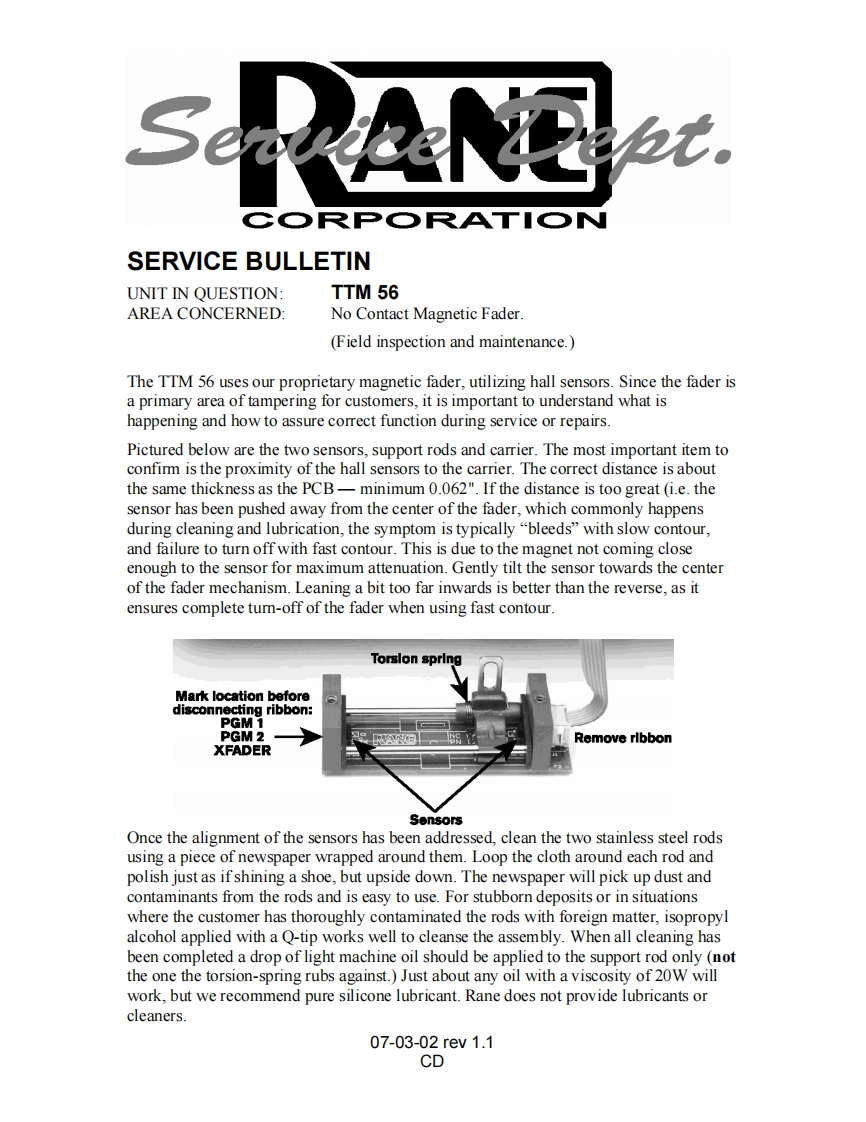

○RPRATI○NSERVICE BULLETINUNIT IN QUESTION:TTM 56AREA CONCERNED:No Contact Magnetic Fader.(Field inspection and maintenance.)The TTM 56 uses our proprietary magnetic fader,utilizing hall sensors.Since the fader isa primary area of tampering for customers,it is important to understand what ishappening and how to assure correct function during service or repairs.Pictured below are the two sensors,support rods and carrier.The most important item toconfirm is the proximity of the hall sensors to the carrier.The correct distance is aboutthe same thickness as the PCB-minimum 0.062".If the distance is too great (i.e.thesensor has been pushed away from the center of the fader,which commonly happensduring cleaning and lubrication,the symptom is typically "bleeds"with slow contour,and failure to turn off with fast contour.This is due to the magnet not coming closeenough to the sensor for maximum attenuation.Gently tilt the sensor towards the centerof the fader mechanism.Leaning a bit too far inwards is better than the reverse,as itensures complete tumn-off of the fader when using fast contour.Torslon sprlngMark location beforedisconnecting ribbon:PGM 1PGM2Remove rlbbonXFADERSensorsOnce the alignment of the sensors has been addressed,clean the two stainless steel rodsusing a piece of newspaper wrapped around them.Loop the cloth around each rod andpolish just as if shining a shoe,but upside down.The newspaper will pick up dust andcontaminants from the rods and is easy to use.For stubborn deposits or in situationswhere the customer has thoroughly contaminated the rods with foreign matter,isopropylalcohol applied with a Q-tip works well to cleanse the assembly.When all cleaning hasbeen completed a drop of light machine oil should be applied to the support rod only (notthe one the torsion-spring rubs against.)Just about any oil with a viscosity of 20W willwork,but we recommend pure silicone lubricant.Rane does not provide lubricants orcleaners.07-03-02rev1.1CD

请登录后查看评论内容