第1页 / 共8页

第2页 / 共8页

试读已结束,还剩6页,您可下载完整版后进行离线阅读

THE END

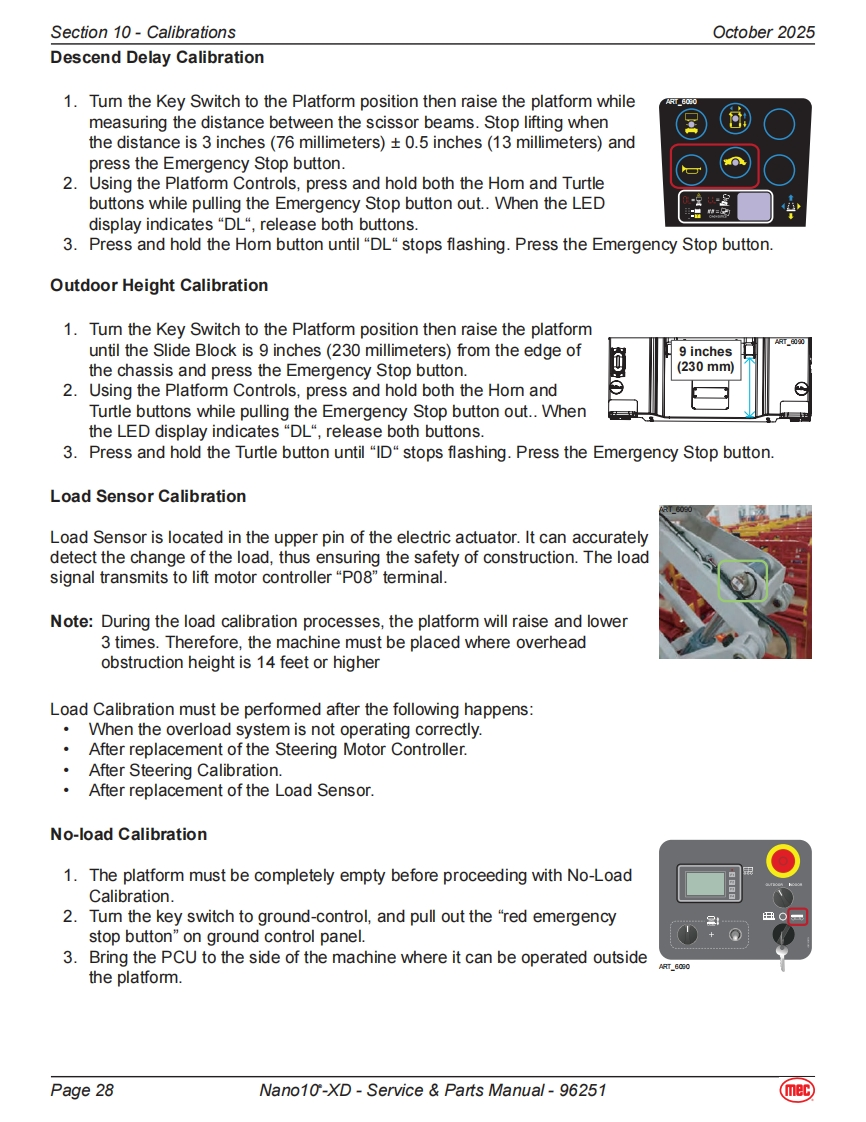

Section 10-CalibrationsOctober 2025CalibrationsCalibration InformationCalibration must be done to ensure proper and safe operation.Each calibration section explains thenature of the calibration and when it should be performed.Tilt Sensor CalibrationThe Tilt Sensor monitors chassis level.The maximum X-axis tilt angle is1.5°and the maximum Y-axis direction is3°.When the machine is raised,the tilt sensor will monitor the angle valueof the chassis in real time.If the tilt angle of the chassis exceeds max tiltangle,the alarm will sound and functions will stop.ART_6090Calibration must be performed when the Level Sensor indication is not accurate or after replacing it.Calibrate Tilt Sensor1.Drive the machine onto level ground.2.Find the reset button on the side of the sensor:"SET ZERO".3.Press and the hold the "SET ZERO"button until the indicatorlight flashes alternatively between red and green.4.Press the "SET ZERO"button 3 times in a row,then theindicator light will stop flashing and the green light stays on.ART_58835.Calibration is complete.Angle Sensor CalibrationThe Angle Sensor is located on the linkage beam,it monitors the heightof the platform by monitoring the angle of the linkage beam in real time.Angle Sensor Calibration must be performed in conjunction with LoadCalibrations or after sensor replacement.Calibrate Angle Sensor1.Refer to the picture to the right and lift the platform halfway.Toensure that the platform is lifted halfway up,lift the platform until thedistance between the beams is 12.5 inches or 317mm.2.Press and the hold the "SET ZERO button until the indicator lightflashes altematively between red and green.3.Press the "SET ZERO"button 3 times in a row,then the indicatorlight will stop flashing and the green light stays on.4.Calibration is complete.Page 27Nano10-XD-Service Parts Manual-96251(mec)

请登录后查看评论内容