第1页 / 共13页

第2页 / 共13页

试读已结束,还剩11页,您可下载完整版后进行离线阅读

THE END

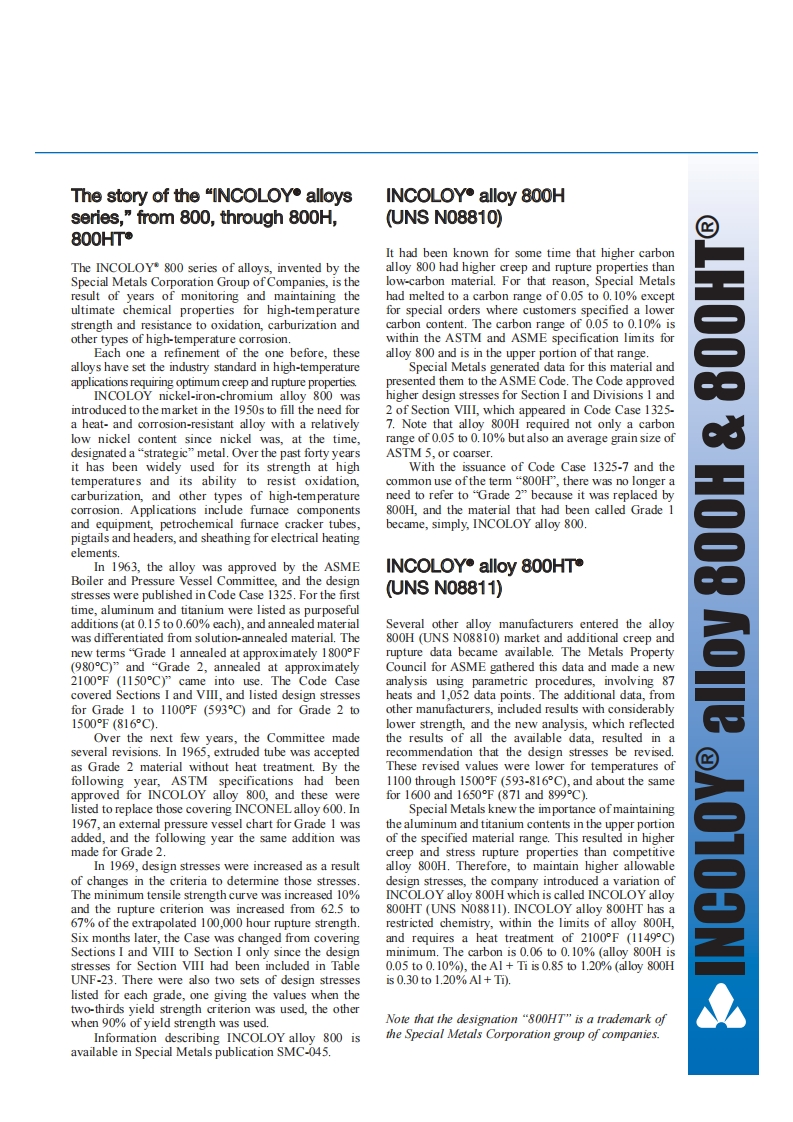

The story of the "INCOLOY alloysINCOLOY alloy 800Hseries,"from 800,through 800H,UNSN08810)800HTIt had been known for some time that higher carbonThe INCOLOY"800 series of alloys,invented by thealloy 800 had higher creep and rupture properties thanSpecial Metals Corporation Group of Companies,is thelow-carbon material.For that reason.Special Metalsresult of years of monitoring and maintaining thehad melted to a carbon range of 0.05 to 0.10%exceptultimate chemical properties for high-temperaturefor special orders where customers specified a lowerstrength and resistance to oxidation,carburization andcarbon content.The carbon range of 0.05 to 0.10%isother types of high-temperature corrosion.within the ASTM and ASME specification limits forEach one a refinement of the one before,thesealloy 800 and is in the upper portion of that range.alloys have set the industry standard in high-temperatureSpecial Metals generated data for this material andapplications requiring optimum creep and rupture propertiespresented them to the ASME Code.The Code approvedINCOLOY nickel-iron-chromium alloy 800 washigher design stresses for Section I and Divisions 1 andintroduced to the market in the 1950s to fill the need for2 of Section VIII,which appeared in Code Case 1325-a heat-and corrosion-resistant alloy with a relatively7.Note that alloy 800H required not only a carbonlow nickel content since nickel was,at the timerange of 0.05 to 0.10%but also an average grain size ofdesignated a "strategic"metal.Over the past forty yearsASTM 5,or coarser.it has been widely used for its strength at highWith the issuance of Code Case 1325-7 and thetemperatures and its ability to resist oxidation,common use ofthe term "800H",there was no longer acarburization,and other types of high-temperatureneed to refer to"Grade 2"because it was replaced bycorrosion.Applications include furnace components800H.and the material that had been called Grade 1and equipment,petrochemical furnace cracker tubes,became,simply,INCOLOY alloy 800.pigtails and headers,and sheathing for electrical heatingelements.In 1963,the alloy was approved by the ASMEINCOLOY●alloy80oHTBoiler and Pressure Vessel Committee,and the designstresses were published in Code Case 1325.For the firstUNSN08811)time,aluminum and titanium were listed as purposefuladditions (at 0.15 to 0.60%each),and annealed materialSeveral other alloy manufacturers entered the alloywas differentiated from solution-annealed material.The800H (UNS N08810)market and additional creep andnew terms"Grade 1 annealed at approximately 1800Frupture data became available.The Metals Property(980C)"and "Grade 2,annealed at approximatelyCouncil for ASME gathered this data and made a new2100℉(1150C)”came into use.The Code Caseanalysis using parametric procedures,involving 87covered Sections I and VIll,and listed design stressesheats and 1,052 data points.The additional data,fromfor Grade 1 to 1100F (593C)and for Grade 2 toother manufacturers,included results with consider

请登录后查看评论内容