第1页 / 共3页

第2页 / 共3页

试读已结束,还剩1页,您可下载完整版后进行离线阅读

THE END

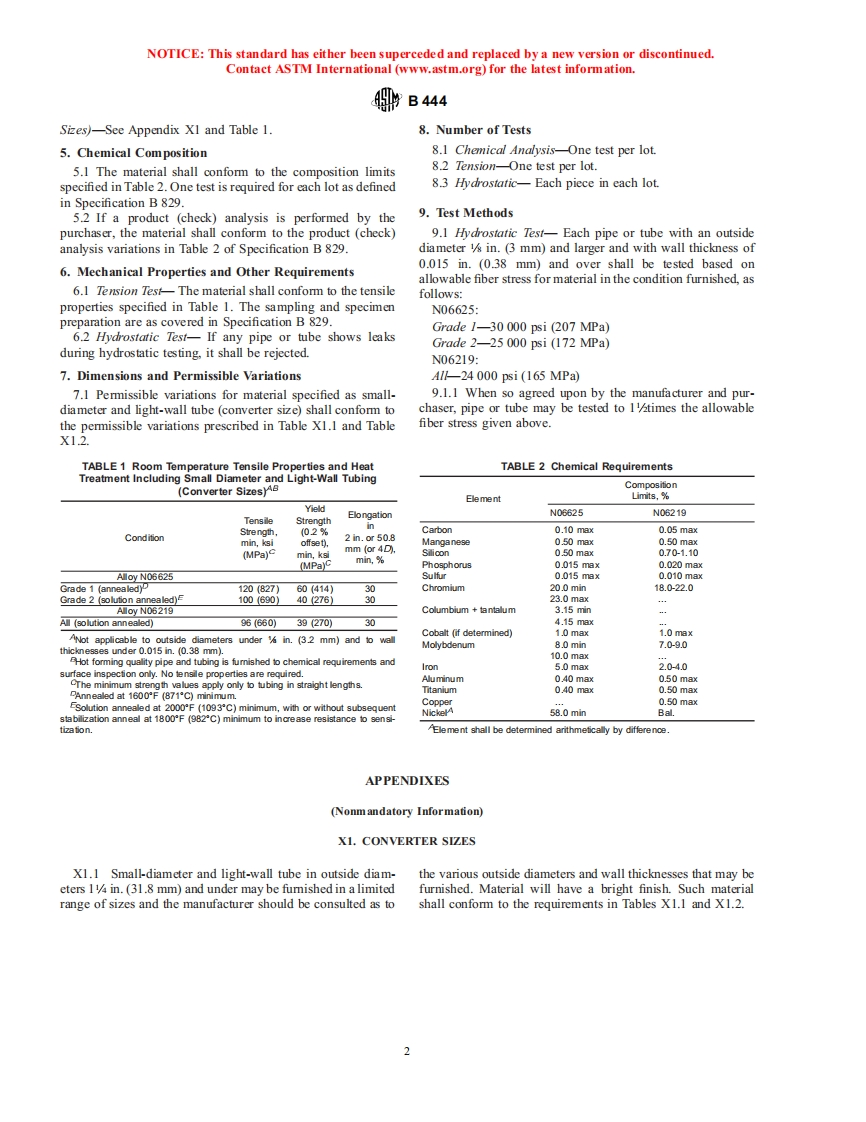

NOTICE:This standard has either been superceded and replaced by a new version or discontinuedContact ASTM International (www.astm.org)for the latest information.Designation:B444-00*1NTERNATIONALStandard Specification forNickel-Chromium-Molybdenum-Columbium Alloys(UNS N06625)and Nickel-Chromium-Molybdenum-SiliconAlloy (UNS N06219)*Pipe and TubeThis standard is issued under the fixed designation B 444;the number immediately following the designation indicates the year oforiginal adoption or,in the case of revision,the year of last revision.A mumber in parentheses indicates the year of last reapproval.Asuperscript epsilon ()indicates an editorial change since the last revision or reapprovalThis stanlard has been approved for use by agencies of the Deparinent of Defense.Nor-Sections 1.1 .2,4.1.3.1,and 9.1 were editorially altered in January 2001.1.ScopeB 829 Specification for General Requirements for Nickel1.1 This specification2covers nickel-chromium-and Nickel Alloy Seamless Pipe and Tube3molybdenum-columbium alloy (UNS N06625)and nickel-chromium-molybdenum-silicon alloy (UNS N06219)*in the3.General Requirementform of cold-worked seamless pipe and tube.The general3.1 Material furnished under this specification shall con-requirements for pipe and tube are covered by Specificationform to the applicable requirements of Specification B 829B829.unless otherwise provided herein.1.1.1 UNS N06625 products are fumished in two grades of4.Ordering Informationdifferent heat-treated conditions:1.1.1.1 Grade (annealed)-Material is normally employed4.1 Orders for material to this specification shall includein service temperatures up to 1100F (593C).information with respect to the following:1.1.1.2 Grade 2 (solution annealed)-Material is normally4.1.1 Alloy name or UNS number,employed in service temperatures above 1100F(593C)when4.1.2 ASTM designation,resistance to creep and rupture is required.4.1.3 Condition (temper)(see 1.1.1,1.1.2,Section 6,andAppendix XI and Appendix X2),Nom 1-Hot-working or reannealing may change properties signifi-4.1.3.1 If neither grade of N06625 is specified,Grade I willcantly,depending on working history and temperaturesbe supplied.1.1.2 Alloy UNS N06219 is supplied in solution annealed4.1.4 Finish (See Appendix X2),condition only.4.1.5 Dimensions:1.2 The following precautionary caveat pertains only to the4.1.5.1 Tube-Specify outside diameter and nominal ortest methods portion,Section 9,of this specification:Thisminimum wall,standard does not purport to address all of the safety concerns.4.1.5.2 Pipe-Specify standard pipe size and schedule,if any,associated with its use.It is the responsibility of the user4.1.5.3 Length-Cut to length or random,of this standard to establish appropriate safety and health4.1.6 Ouantity-Feet (or metres)or number of pieces,practices and determine the applicability of regulatory limita-4.1.7 Hydrostatic Pressure Requirements-Specify testfions prior to use.pressure if other than required by 9.1.1.4.1.8 Certifi

请登录后查看评论内容