第1页 / 共3页

第2页 / 共3页

试读已结束,还剩1页,您可下载完整版后进行离线阅读

THE END

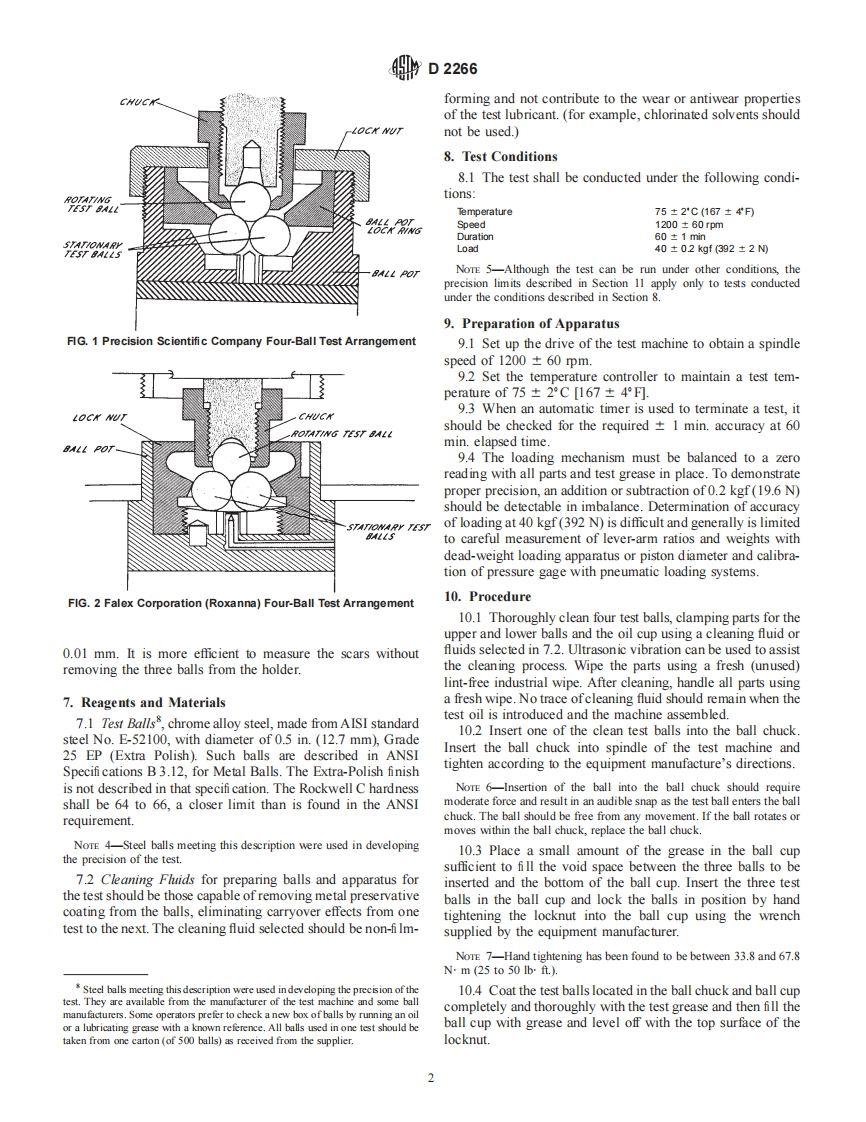

Designation:D 2266-01An American Nafional StandardNTERNATIONALStandard Test Method forWear Preventive Characteristics of Lubricating Grease(Four-Ball Method)1This standard is issued under the fixed designation D2266;the number immediately following the designation indicates the year oforiginal adoption or,in the case of revision,the year of last revision.A number in parentheses indicates the year of last reapproval.Asuperscript epsilon (e)indicates an editorial change since the last revision or reapproval.This st method has been adopted for use by goverment agencies to rplace Method 6514 of Federal Test Method Standard No.791b.1.Scopefourth 1/zin.diameter steel ball,referred to as the top ball,is1.1 This test method covers the determination of the wearpressed with a force of 40 kgf (392 N)into the cavity formedpreventive characteristics of greases in sliding steel-on-steelby the three clamped balls for three-point contact.The tem-applications.It is not intended to predict wear characteristicsperature of the lubricating grease specimen is regulated at 75Cwith metal combinations other than steel-on-steel or to evaluate(167 F)and then the top ball is rotated at 1200 rpm for 60 min.the extreme pressure characteristics of the grease.Lubricants are compared by using the average size of the scar1.2 The values stated in SI units are to be regarded as thediameters worn on the three lower clamped balls.standard except where the test apparatus or consumable partsNorE 1-Because of differences in the construction of the variousare only available in other units.In such cases,these will bemachines on which the four-ball test can be made,the manufacturer'sregarded as standard.The values given in parentheses are forinstructions should be consulted for proper machine setup and operation.infommation only.NorE 2-Although the test can be run under other test parameters,the1.3 This standard does not purport to address all of theprecision noted in Section 11 can vary when testing with other than testsafety problems,if any.associated with its use.It is theparameters listed in Section 8.responsibility of the user of this standard to establish appro-5.Significance and Usepriate safety and health practices and determine the applica-5.1 The four-ball wear-test method can be used to determinebility of regulatory limitations prior to use.the relative wear-preventing properties of greases under the test2.Referenced Documentsconditions and if the test conditions are changed the relative2.1 ASTM Standards:ratings may be different.No correlation has been establishedbetween the four-ball wear test and field service.The testD 4172 Test Method for Wear Preventive Characteristics ofLubricating Fluid (Four-Ball Method)2method cannot be used to differentiate between ExtremeD 6300 Practice for Determination of Precision and BiasPressure (EP)and Non-Extreme Pressure (Non-EP)Greases.5Data for Use in Test Methods for Petroleum Products and6.ApparatusLubricants36.1 Four-Ball Wear-Tester and

请登录后查看评论内容