第1页 / 共5页

第2页 / 共5页

试读已结束,还剩3页,您可下载完整版后进行离线阅读

THE END

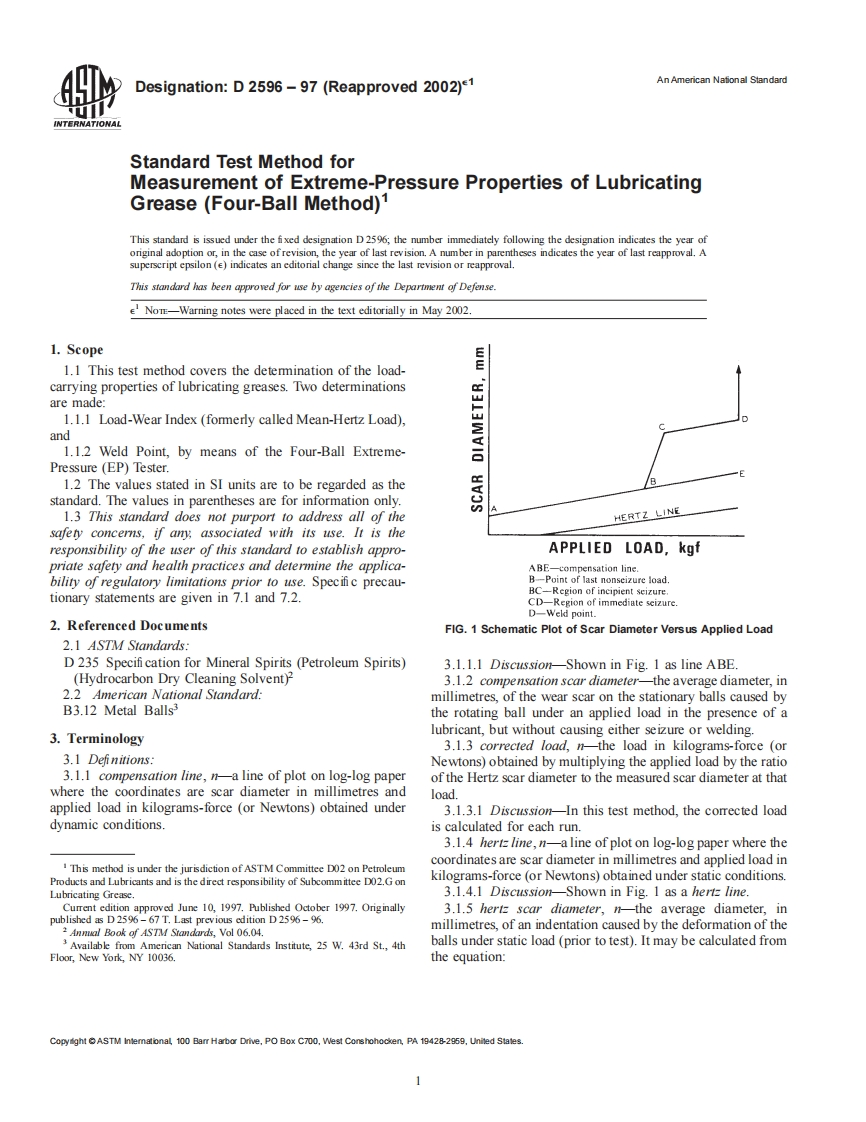

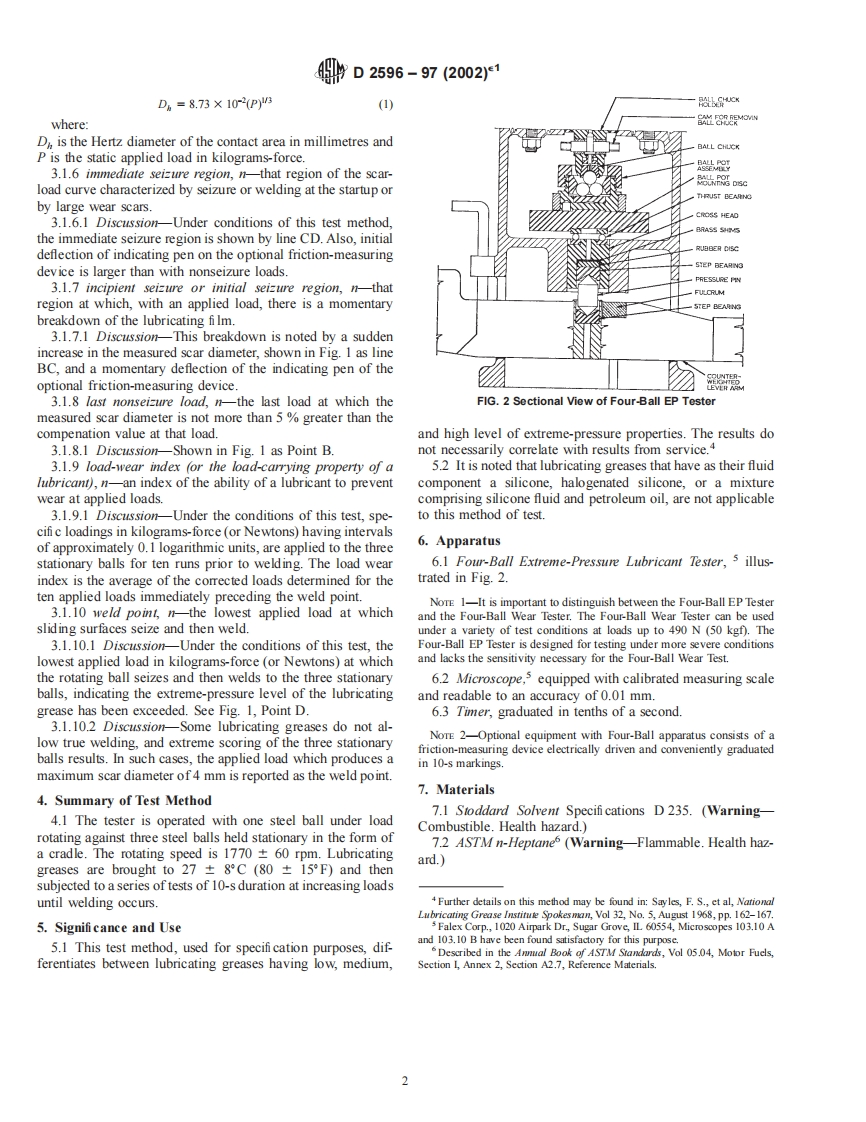

Designation:D 2596-97 (Reapproved 2002)1An American National StandardINTERNATIONALStandard Test Method forMeasurement of Extreme-Pressure Properties of LubricatingGrease (Four-Ball Method)1This standard is issued under the fixed designation D2596;the number immediately following the designation indicates the year oforiginal adoption or,in the case ofrevision,the year of last revision.A number in parentheses indicates the year of last reapproval.Asuperscript epsilon (E)indicates an editorial change since the last revision or reapproval.This standard has been approved for use by agencies of the Department of Defense.e'Nom-Warning notes were placed in the text editorially in May 20021.Scope1.1 This test method covers the determination of the load-carrying properties of lubricating greases.Two determinationsare made:1.1.1 Load-Wear Index(formerly called Mean-Hertz Load),and1.1.2 Weld Point,by means of the Four-Ball Extreme-Pressure (EP)Tester.1.2 The values stated in SI units are to be regarded as thestandard.The values in parentheses are for information only.1.3 This standard does not purport to address all of theHERTZ LINEsafety concerns,if any,associated with its use.It is theresponsibility of the user of this standard to establish appro-APPLIED LOAD,kgfpriate safety and health practices and determine the applica-ABE-compensation line.bility of regulatory limitations prior to use.Specific precau-B-Point of last nonseizure load.tionary statements are given in 7.1 and 7.2.BC-Region of incipient seizureCD-Region of immediate seizurc.D-Weld point.2.Referenced DocumentsFIG.1 Schematic Plot of Scar Diameter Versus Applied Load2.1 ASTM Standards:D 235 Specifi cation for Mineral Spirits (Petroleum Spirits)3.1.1.1 Discussion-Shown in Fig.1 as line ABE.(Hydrocarbon Dry Cleaning Solvent)3.1.2 compensation scar diameter-the average diameter,in2.2 American National Standard:millimetres,of the wear scar on the stationary balls caused byB3.12 Metal Balls'the rotating ball under an applied load in the presence of a3.Terminologylubricant,but without causing either seizure or welding.3.1.3 corrected load,n-the load in kilograms-force (or3.1 Defnitions.Newtons)obtained by multiplying the applied load by the ratio3.1.1 compensation line,na line of plot on log-log paperof the Hertz scar diameter to the measured scar diameter at thatwhere the coordinates are scar diameter in millimetres andload.applied load in kilograms-force (or Newtons)obtained under3.1.3.1 Discussion-In this test method,the corrected loaddynamic conditionsis calculated for each run.3.1.4 hertz line,n-a line of plot on log-log paper where theThis method is under the jurisdiction of ASTM Committee D02 on Petroleumcoordinates are scar diameter in millimetres and applied load inProducts and Lubricants and is the direct responsibility of Subcommittee D02.G onkilograms-force (or Newtons)obtained under static conditions.Lubricating Grease3.1.4.1 Discussion-Shown in Fig.1 as a hertz line.Current edition app

请登录后查看评论内容