第1页 / 共6页

第2页 / 共6页

试读已结束,还剩4页,您可下载完整版后进行离线阅读

THE END

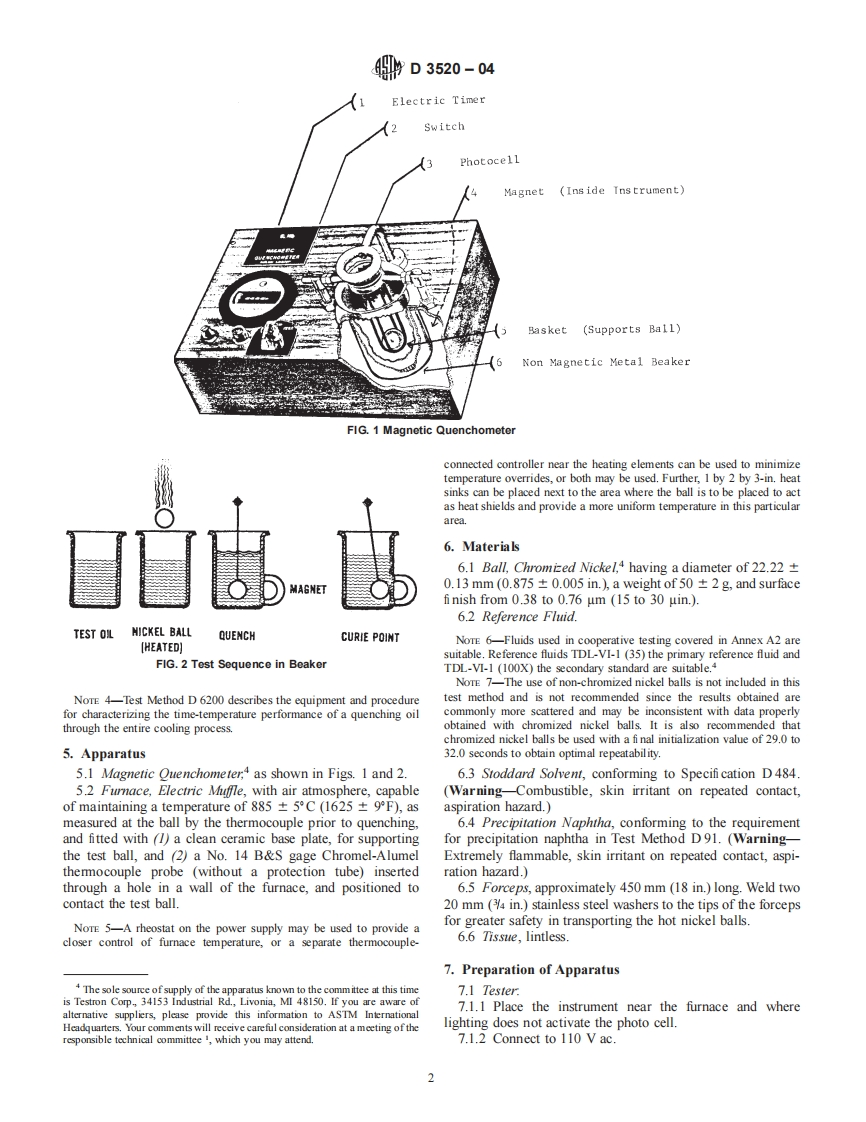

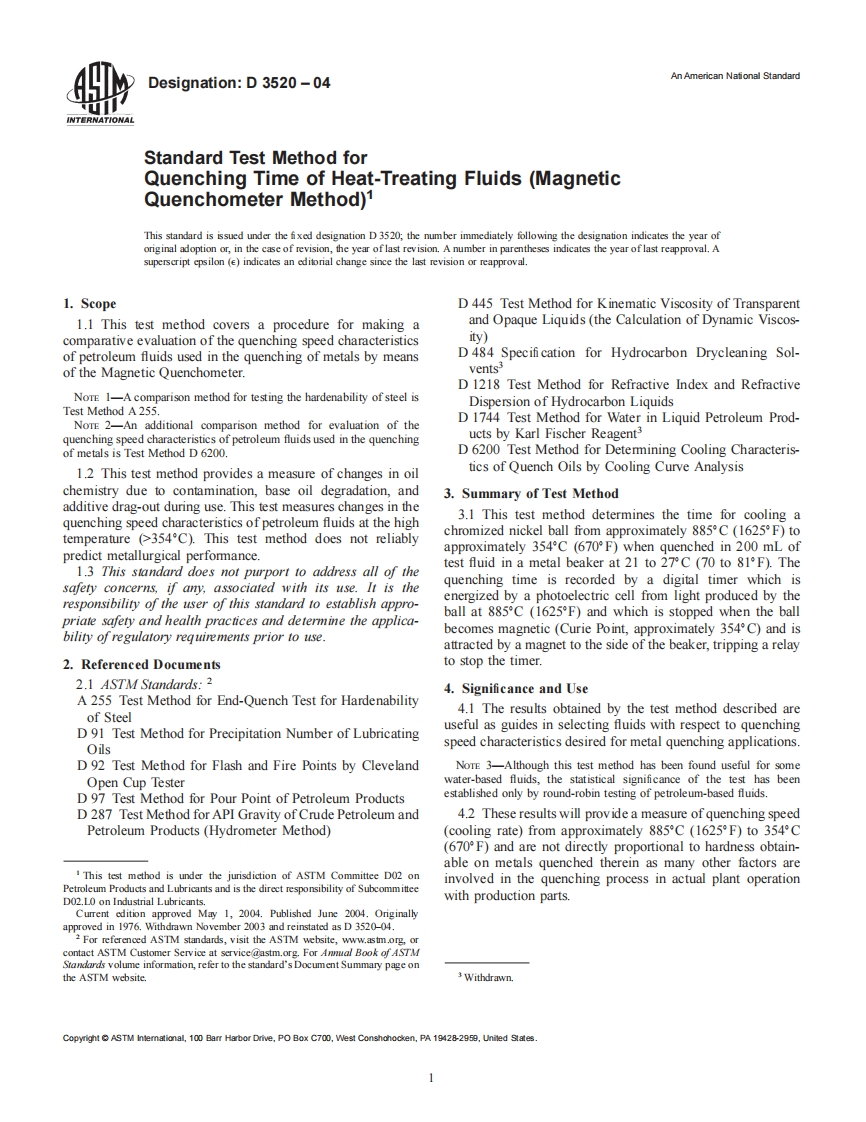

Designation:D 3520-04An American Nafional StandardNTERNATIONALStandard Test Method forQuenching Time of Heat-Treating Fluids(MagneticQuenchometer Method)1This standard is issued under the fixed designation D3520;the number immediately following the designation indicates the year oforiginal adoption or,in the case of revision,the year of last revision.A number in parentheses indicates the year of last reapproval.Asuperscript epsilon (e)indicates an editorial change since the last revision or reapproval.1.ScopeD 445 Test Method for Kinematic Viscosity of Transparent1.1 This test method covers a procedure for making aand Opaque Liquids(the Calculation of Dynamic Viscos-comparative evaluation of the quenching speed characteristicsity)of petroleum fluids used in the quenching of metals by meansD484 Specifi cation for Hydrocarbon Drycleaning Sol-of the Magnetic Quenchometer.vents3D 1218 Test Method for Refractive Index and RefractiveNorE 1-A comparison method for testing the hardenability of steel isDispersion of Hydrocarbon LiquidsTest Method A 255.NorE 2-An additional comparison method for evaluation of theD 1744 Test Method for Water in Liquid Petroleum Prod-quenching speed characteristics of petroleum fluids used in the quenchingucts by Karl Fischer Reagent3of metals is Test Method D 6200.D 6200 Test Method for Determining Cooling Characteris-1.2 This test method provides a measure of changes in oiltics of Quench Oils by Cooling Curve Analysischemistry due to contamination,base oil degradation,and3.Summary of Test Methodadditive drag-out during use.This test measures changes in thequenching speed characteristics of petroleum fluids at the high3.1 This test method determines the time for cooling atemperature (>354C).This test method does not reliablychromized nickel ball from approximately 885C(1625F)topredict metallurgical performance.approximately 354C (670F)when quenched in 200 mL oftest fluid in a metal beaker at 21 to 27C (70 to 81F).The1.3 This standard does not purport to address all of thesafety concerns,if any,associated with its use.It is thequenching time is recorded by a digital timer which isresponsibility of the user of this standard to establish appro-energized by a photoelectric cell from light produced by thepriate safety and health practices and determine the applica-ball at 885C (1625F)and which is stopped when the ballbility of regulatory requirements prior to use.becomes magnetic (Curie Point,approximately 354C)and isattracted by a magnet to the side of the beaker,tripping a relay2.Referenced Documentsto stop the timer2.1 ASTM Standards:24.Significance and UseA 255 Test Method for End-Quench Test for Hardenabilityof Steel4.1 The results obtained by the test method described areuseful as guides in selecting fluids with respect to quenchingD 91 Test Method for Precipitation Number of LubricatingOilsspeed characteristics desired for metal quenching applications.D 92 Test Method for Flash and Fire Points by ClevelandNorE 3-Although

请登录后查看评论内容