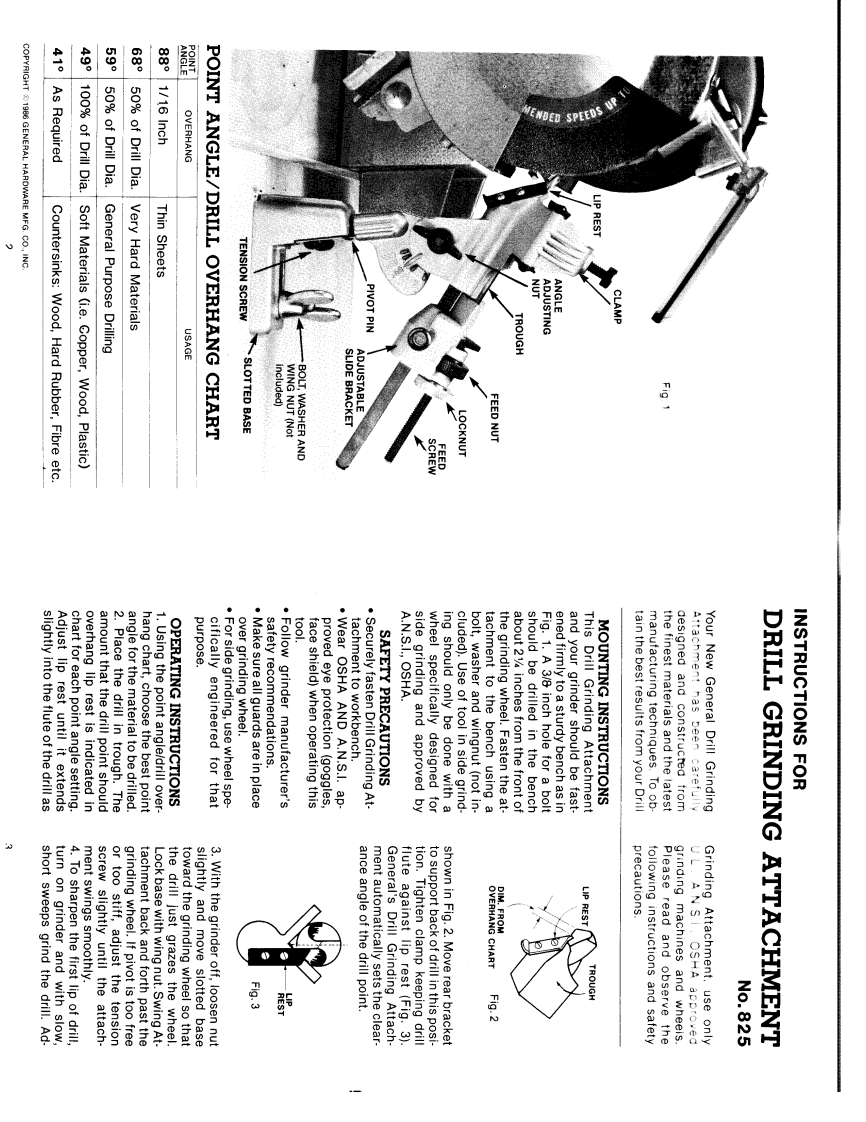

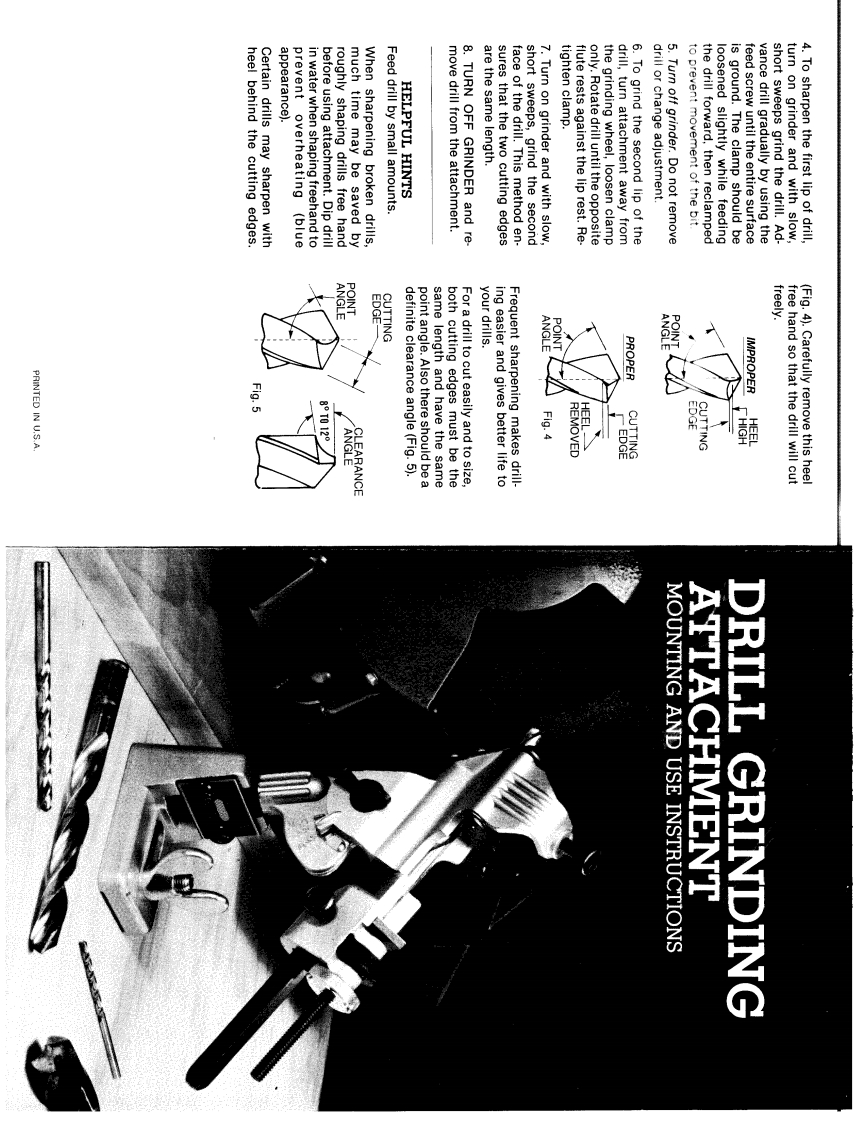

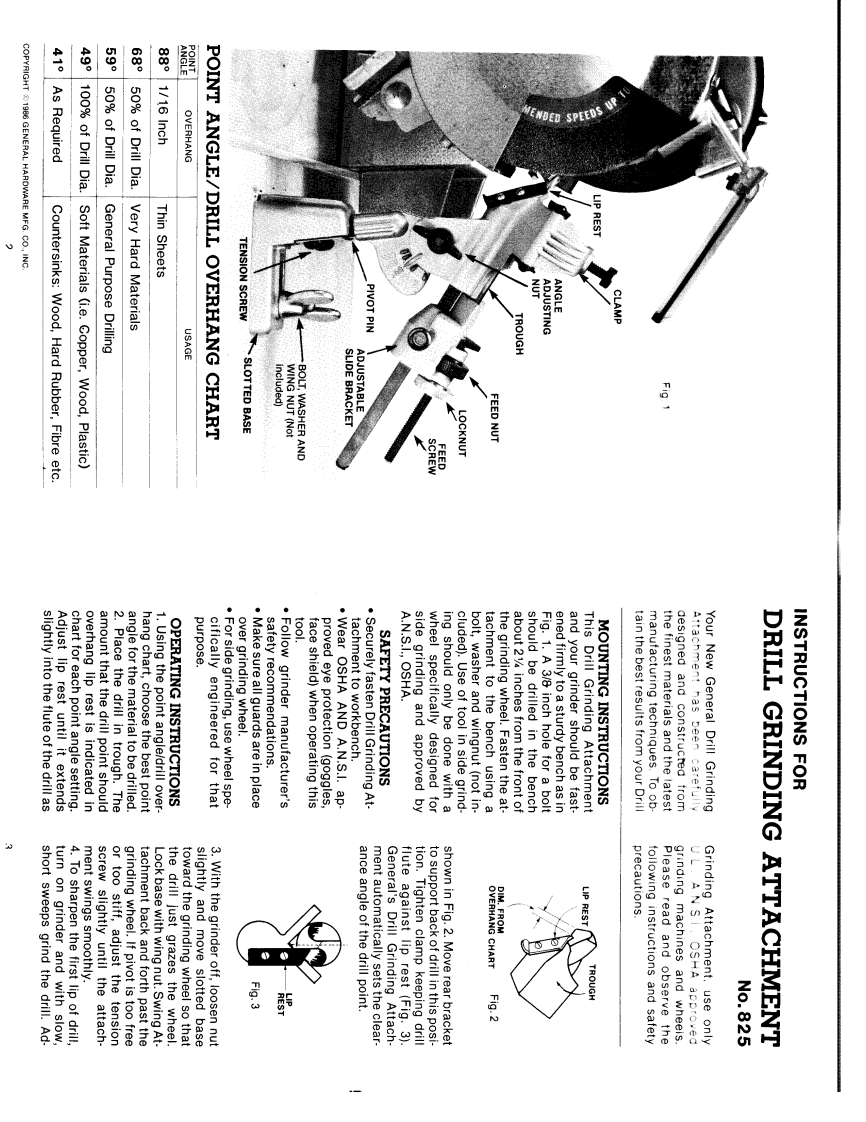

41 As Required醒COPYRIGHT 1986 GENERAL HAROWARE MFG.CO..INC49100%of Drill Dia.Soft Materials (i.e.Copper,Wood,Plastic)5950%of Drill Dia.50%of Drill Dia.881/16 InchOVERHANGCountersinks:Wood,Hard Rubber,Fibre etc.General Purpose DrillingVery Hard MaterialsThin SheetsPOINT ANGLE/DRILL OVERHANG CHARTLIP RESTTENSION SCREWPIVOT PINNUTANGLECLAMPUSAGETROUGHADJUSTINGSLOTTED BASEincluded)WING NUT (NotBOLT,WASHER ANDSLIDE BRACKETADJUSTABLEOCKNUTFEED NUFEEDtool.slightly into the flute of the drill asAdjust lip rest until it extendschart for each point angle setting.overhang lip rest is indicated inamount that the drill point should2.Place the drill in trough.Theangle for the material to be drilled.hang chart,choose the best point1.Using the point angle/drill overOPERATING INSTRUCTIONScifically engineered for thatFor side grinding,use wheel speover grinding wheel.Make sure all guards are in placesafety recommendations.Follow grinder manufacturer'sface shield)when operating thisproved eye protection(goggles,Wear OSHA AND A.N.S.I.aptachment to workbench.Securely fasten Drill Grinding At-SAFETY PRECAUTIONSA.N.S.I.,OSHA.side grinding and approved bywheel specifically designed foring should only be done with acluded).Use of tool in side grind.bolt,washer and wingnut (not in-tachment to the bench using athe grinding wheel.Fasten the at-about 2%inches from the front ofshould be drilled in the benchFig.1.A 3/8 inch hole for a boltened firmly to a sturdy bench as inand your grinder should be fast-This Drill Grinding AttachmentMOUNTING INSTRUCTIONStain the best results from your Drillmanutacturing techniques.To obthe finest materials and the latestdesigned and constructea fromAttachment has been carefullyYour New General Drill GrindingINSTRUCTIONS FORshort sweeps grind the drill.Ad.turn on grinder and with slow4.To sharpen the first lip of drill,ment swings smoothly.screw slightly until the attach.or too stiff,adjust the tensiongrinding wheel.If pivot is too freetachment back and forth past theLock base with wing nut.Swing At.the drill just grazes the wheel.toward the grinding wheel so thatslightly and move slotted base3.With the grinder off,loosen nutance angle of the drill point.ment automatically sets the clear-General's Drill Grinding Attachflute against lip rest (Fig.3)tion.Tighten clamp keeping drillto support back of drill in this posi-shown in Fig.2.Move rear bracketOVERHANG CHARTDIM·FROMprecautions.UGHF19:2following instructions and safetyPlease read and observe thegrinding machines and wheels.U L.A N S.1..OSHA approvedGrinding Attachment.use onlyDRILL GRINDING ATTACHMENTNo-825

请登录后查看评论内容