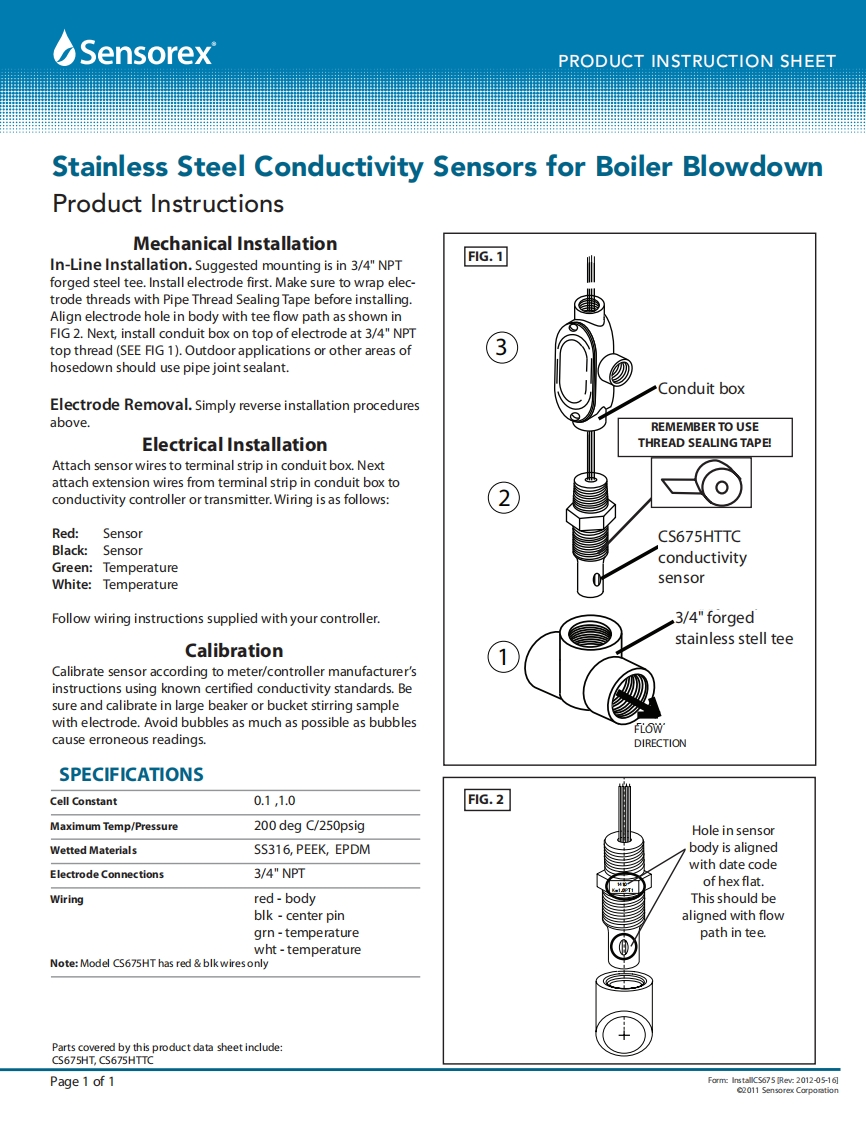

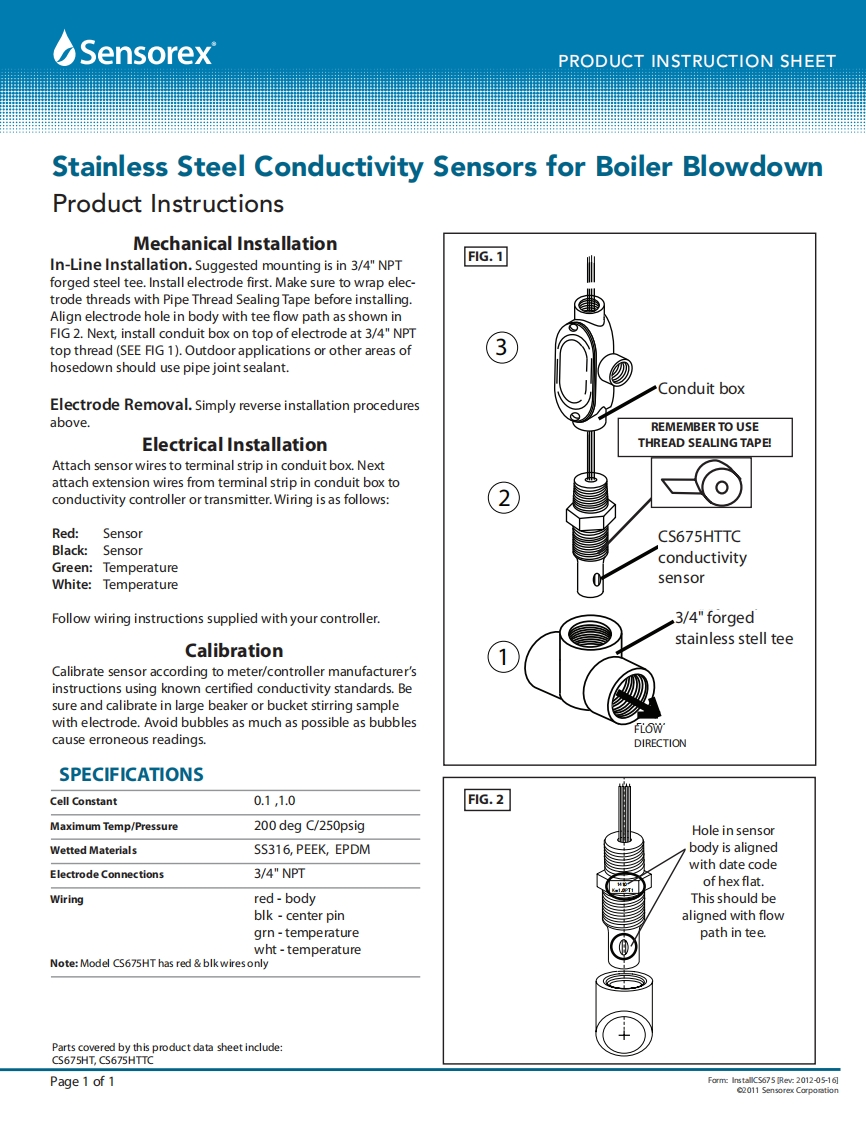

SensorexPRODUCT INSTRUCTION SHEETStainless Steel Conductivity Sensors for Boiler BlowdownProduct InstructionsMechanical InstallationIn-Line Installation.Suggested mounting is in 3/4"NPTFIG.1forged steel tee.Install electrode first.Make sure to wrap elec-trode threads with Pipe Thread Sealing Tape before installing.Align electrode hole in body with tee flow path as shown inFIG 2.Next,install conduit box on top of electrode at 3/4"NPTtop thread(SEE FIG 1).Outdoor applications or other areas ofhosedown should use pipe joint sealant.Conduit boxElectrode Removal.Simply reverse installation proceduresabove.REMEMBER TO USEElectrical InstallationTHREAD SEALING TAPE!Attach sensor wires to terminal strip in conduit box.Nextattach extension wires from terminal strip in conduit box toconductivity controller or transmitter.Wiring is as follows:Red:SensorCS675HTTCBlack:SensorconductivityGreen:TemperatureWhite:TemperaturesensorFollow wiring instructions supplied with your controller..3/4"forgedstainless stell teeCalibrationCalibrate sensor according to meter/controller manufacturer'sinstructions using known certified conductivity standards.Besure and calibrate in large beaker or bucket stirring samplewith electrode.Avoid bubbles as much as possible as bubblesFLOWcause erroneous readings.DIRECTIONSPECIFICATIONSCell Constant0.1,1.0FIG.2Maximum Temp/Pressure200 deg C/250psigHole in sensorWetted MaterialsSS316,PEEK,EPDMbody is alignedwith date codeElectrode Connections3/4"NPTof hex flat.Wiringred-bodyThis should beblk -center pinaligned with flowgrn-temperaturepath in tee.wht-temperatureNote:Model CS675HT has red blk wiresonlyParts covered by this product data sheet include:CS675HT,CS675HTTCPage 1 of 1Form:InstallCS675 [Rev:2012-05-16]2011 Sensorex Corportion

请登录后查看评论内容